Preventive Maintenance and Technical Support for EPS Machines

Scheduled Preventive Maintenance Programs

We implement customized preventive maintenance schedules designed specifically for your EPS foam production line. Our approach goes beyond standard checklists—each program is built based on machine model, usage frequency, environmental conditions, and past maintenance history.

Services include routine mechanical inspections, electrical testing, lubrication routines, pressure system balancing, and replacement of time-sensitive parts. By adhering to a proactive maintenance plan, you significantly reduce the risk of sudden breakdowns, extend the lifecycle of critical components, and maintain uninterrupted production. A structured plan improves operator confidence and makes compliance with internal and external safety standards effortless.

Emergency Breakdown Response

When your production line unexpectedly stops, every second counts. Our rapid-response technical team is trained to deliver immediate on-site or remote troubleshooting for EPS machine breakdowns. Equipped with mobile diagnostic tools, service kits, and access to real-time system data, our experts can isolate faults quickly and initiate corrective action.

We also maintain critical spare part inventories for expedited repairs, helping you avoid delays caused by long procurement cycles. Our goal is to minimize total downtime, protect output schedules, and ensure operational continuity even under the most stressful conditions.

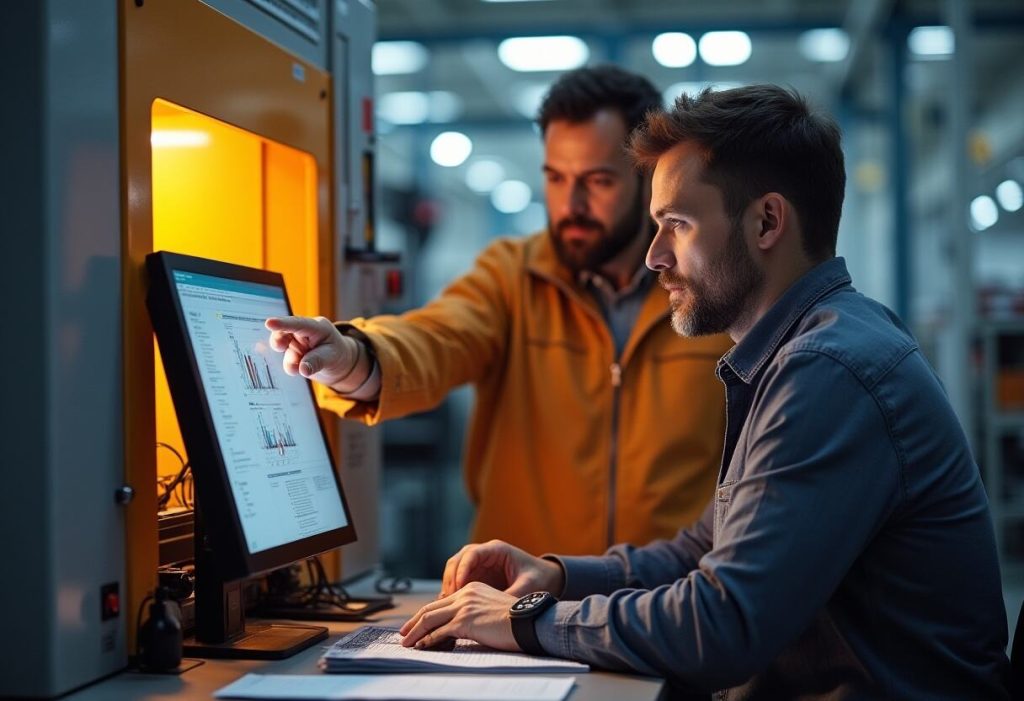

System Diagnostics and Performance Audits

We provide in-depth system diagnostics and performance audits as part of our long-term equipment health strategy. These audits include real-time evaluation of pressure regulation, thermal distribution, mechanical wear levels, and energy efficiency indicators.

Our team uses smart diagnostic sensors and historical data to spot inefficiencies before they become failures. You receive detailed technical reports along with clear recommendations for component tuning, upgrades, or replacements. This data-driven approach ensures predictive maintenance, optimized machine performance, and measurable ROI over time.

Technical Support and Operator Assistance

Beyond equipment, our support extends directly to your workforce. We deliver structured training sessions, both online and in person, to ensure your machine operators fully understand daily operation, control interfaces, error codes, and routine adjustments. We also offer multilingual troubleshooting guides, video modules, and access to remote assistance.

Our goal is to empower your team to respond confidently to issues, minimize downtime due to user error, and maintain high operational standards. A well-trained operator team is essential to achieving maximum uptime, consistent quality, and safe production environments.