Automation Solutions for EPS Production Lines

Integrated Control Systems for Full Automation

Our integrated control systems form the backbone of a fully automated EPS production environment. These systems coordinate every phase of the manufacturing process—from material feeding and pre-expansion to molding and cutting—within a single, centralized interface.

Advanced PLCs and HMIs enable real-time control, allowing operators to adjust parameters such as pressure, temperature, and cycle times with precision. Features like remote diagnostics, automatic error detection, and system-wide synchronization help reduce downtime and improve responsiveness. With these technologies in place, manufacturers benefit from streamlined operations, enhanced product consistency, and minimized human intervention.

Conveyor and Handling Automation

To maximize efficiency, we design automated material handling systems that eliminate bottlenecks and manual errors. This includes high-speed conveyor lines, robotic pick-and-place systems, automated lifters, and transfer stations—all working in seamless harmony. These components are engineered for high cycle capacity and gentle handling to preserve foam integrity during transfer.

By replacing manual intervention with synchronized automation, facilities can scale up production without compromising on safety or precision. The result is a significant boost in operational speed, reduced labor dependency, and an overall improvement in process flow reliability.

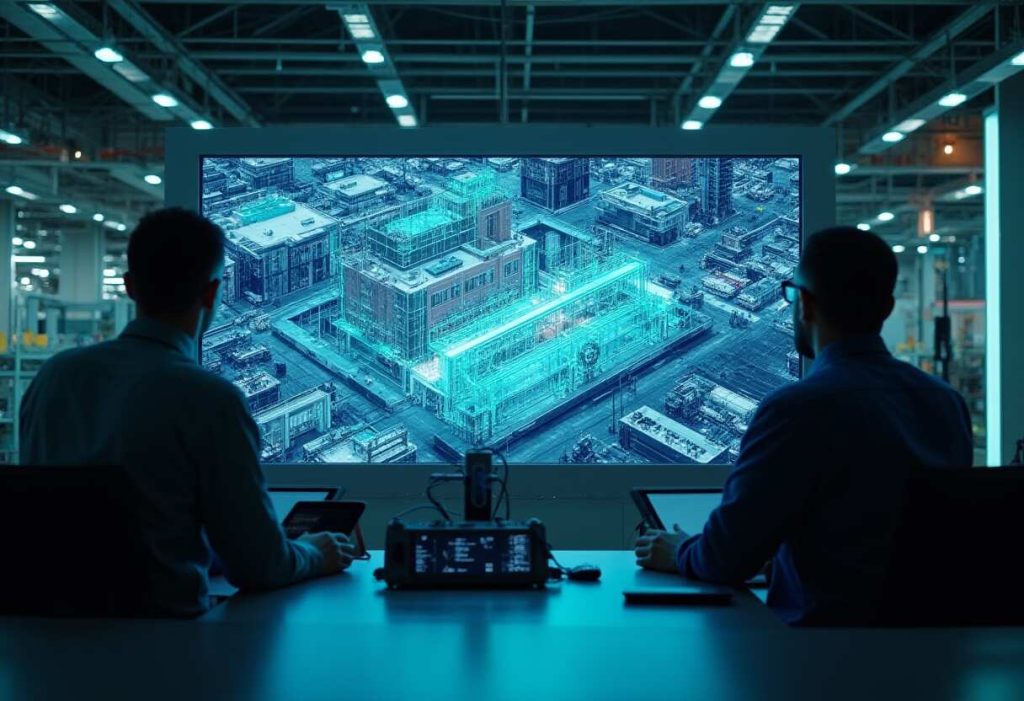

Real-Time Data Monitoring and Analytics

In modern EPS production, data is power. Our automation systems are equipped with intelligent sensor arrays that continuously monitor variables such as steam pressure, material density, line temperature, and mechanical performance. All this data is collected and visualized through interactive dashboards that provide real-time insight into every production event.

Through performance trend analysis, downtime reports, and maintenance forecasting, plant managers can make data-driven decisions that lead to reduced waste, optimized energy consumption, and higher productivity. This level of insight transforms operations from reactive to proactive.

Custom Automation Solutions for Any Plant Size

Every production environment has its unique footprint, workflow, and objectives—which is why we offer tailored automation solutions that adapt to your exact setup. Whether you’re a small manufacturer looking to improve part of your process or a large-scale operation seeking full-line automation, our engineering team designs modular, scalable systems that grow with you.

From on-site evaluations and simulation modeling to system integration and staff training, we manage the entire journey. These custom solutions ensure that your automation investment is precise, future-ready, and fully compatible with your existing infrastructure.